Wethertex Approved Contractors & Applicators: Why Only Certified Installers Should Apply Wethertex Coatings

Image Source: Wethertex.co.uk

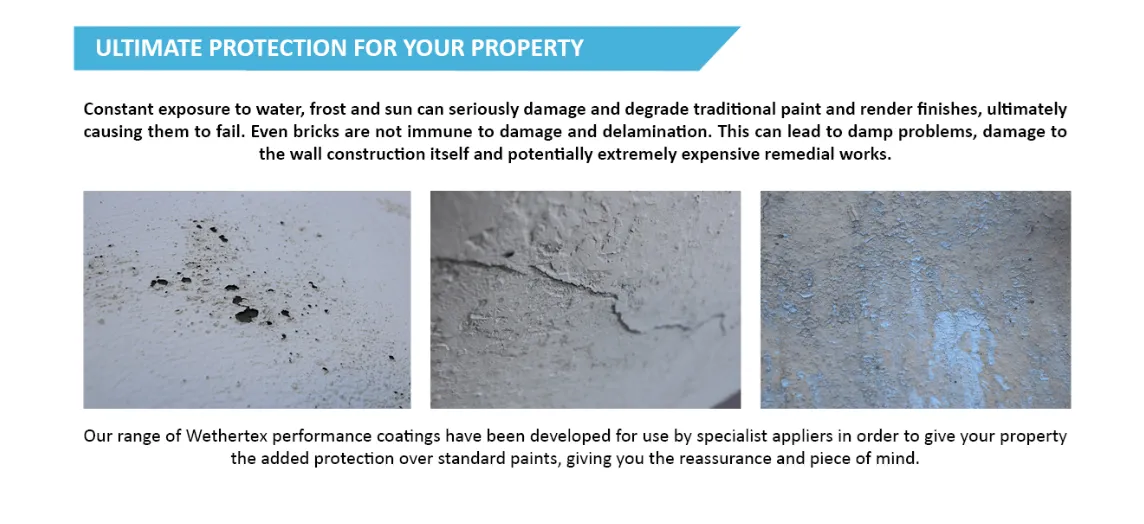

Choosing an exterior wall coating isn’t just about colour or aesthetics — it’s a structural decision that affects the durability, weather resistance, energy performance, and long-term integrity of your home. Wethertex is one of the UK’s leading high-performance coating manufacturers, known for producing industrial-grade systems such as MP44, HPS Flex-Coat Pro, and AX1 primers. But these systems are not comparable to standard masonry paint — they are engineered coatings designed to be installed by trained professionals.

This is why Wethertex Approved Contractors exist. These installers undergo manufacturer-led training, practical application assessments, and ongoing performance audits to ensure that installations meet the strict system requirements. When applied correctly, a Wethertex system can protect a home for up to 20+ years. When applied incorrectly, however, even the best coating can fail early, trap moisture, or compromise the substrate.

This expanded guide gives homeowners everything they need to understand:

- What makes an installer “approved”

- Why the approval matters

- How the systems work

- What happens during a survey

- What to expect during installation

- How to identify genuine certified installers

- Why professional application is essential for the product guarantee

Throughout the article, you’ll also find subtle guidance on why choosing a trusted specialist — such as Pinnacle Wall Coatings — is the safest, most reliable investment for your home.

1. What Is a Wethertex Approved Contractor?

A Wethertex Approved Contractor is a specialist installer who has completed manufacturer training and demonstrated proficiency in applying Wethertex external wall coatings to the correct technical standards. This status is earned — not purchased — and involves several layers of assessment.

Key Criteria That Define an Approved Contractor

1. Manufacturer Training

Approved installers must complete formal training delivered by Wethertex experts. This covers:

- Surface diagnostics

- Moisture behaviour in render substrates

- Product-specific primers

- Flexibility vs. breathability ratios

- Optimal spray equipment settings

- Correct system layering and dry film thickness

Many general decorators have no experience with these specialist processes.

2. Proven Real-World Experience

Approval requires a contractor to demonstrate they:

- Have installed exterior coatings professionally

- Maintain consistent quality across projects

- Use the full Wethertex system (not cheap substitutes)

- Understand building science, not just painting

3. Audits & Ongoing Monitoring

Wethertex does not issue lifetime approval. Contractors must uphold:

- Installation standards

- Repair accuracy

- Correct use of the full system

- Customer satisfaction

- Correct warranty registration

- Approval can be revoked if standards slip.

4. Access to Professional-Only Wethertex Systems

Some products are restricted to approved applicators because they require:

- Specialised equipment

- Controlled application conditions

- Correct technical build-up

This ensures homeowners receive the performance the product was designed for.

In short:

An approved contractor isn’t just a painter. They are a trained exterior coating technician with expert-level product knowledge and installation skill.

2. Why Approval Matters

Many homeowners don’t initially understand the difference between an approved contractor and a standard painter — until it’s too late. Wethertex coatings are high-performance systems that require precise preparation, layering, and application to function as intended.

Here’s why approval matters so much:

1. Manufacturer-Backed Guarantees

Wethertex warranties only apply when:

- The full system is used

- The installer is approved

- The application meets technical guidelines

If a non-approved contractor applies the product, the manufacturer will not support any failures — no matter how good the contractor claims to be.

2. Coating Longevity

Wethertex systems achieve their 15–20+ year lifespan only when:

- The correct primers are used

- The coating is applied at the correct thickness

- Drying times and weather conditions are controlled

- All cracks and structural issues are repaired first

Approved installers understand how each of these variables affects durability.

3. Proper Substrate Preparation

Preparation is everything. Over 90% of coating failures in the UK are due to poor preparation, not defective products.

Approved contractors follow strict prep processes, including:

- Biocide wash

- Render diagnostics

- Crack stitch repairs

- Blown render removal

- Moisture testing

This prevents future issues such as flaking, blistering, cracking, and damp.

4. Access to the Correct System Specification

Different substrates require different coating systems. For example:

- Old pebble-dash → needs deep-penetration primers

- Sand/cement render → needs flexible body coats

- Brickwork → may require Pliolite-based systems

- Previously painted masonry → must be tested for adhesion

An approved installer will correctly specify the system for long-term success.

3. Benefits of Using a Wethertex Approved Contractor

1. Premium Long-Term Protection

Wethertex coatings are proven to outperform standard paints, but they must be applied with precision. Approved installers ensure:

- Correct dry film thickness

- Full surface saturation

- Maximum waterproofing

- Correct curing

- System longevity

These factors directly impact how long the coating lasts.

2. Damp Prevention & Breathability

Incorrect application can trap moisture, leading to internal damp issues. Approved installers:

- Measure substrate moisture

- Install breathable systems

- Avoid sealing moisture inside the wall

This can significantly reduce penetrating damp and associated problems.

3. A Superior Aesthetic Finish

Most Wethertex systems are spray-applied. Approved contractors use:

- Airless spray machines

- Precision nozzles

- High-build application equipment

This ensures a premium, even, textured finish that DIYers or general decorators can’t match.

4. Peace of Mind

Homeowners receive:

- Official guarantee

- Workmanship assurance

- Approved contractor documentation

- Wethertex system certification

This adds value to the home and protects the homeowner if issues arise.

5. Reduced Future Maintenance

Wethertex coatings are designed to:

- Resist algae

- Repel dirt

- Prevent flaking

- Peduce colour fading

- Withstand UK weather conditions

With approved installation, properties typically require no repainting for 15+ years.

Image Source: Wethertex.co.uk

4. Most Popular Wethertex Systems Installed by Approved Contractors

Here is a deeper look at the most commonly installed Wethertex systems and why they require trained installers:

Wethertex MP44 Pliolite® Based Masonry Coating

A solvent-based, high-performance system renowned for:

- Exceptional adhesion

- Extreme weather resistance

- Rainproofing in 20 minutes

- Long-term colour stability

Ideal for exposed coastal or high-wind areas.

Wethertex HPS Flex-Coat Pro

A highly flexible coating engineered to bridge fine cracks and protect older render.

Key benefits include:

- Elasticity

- Durability

- Resistance to micro-cracking

- Smooth or textured finishes

Requires trained application to ensure correct stretching and build-up.

Wethertex AX1 Primer

A deep-penetration primer that:

- Binds unstable surfaces

- Improves adhesion

- Enhances waterproofing performance

- Ensures correct system compatibility

Incorrect primer selection is one of the biggest causes of coating failure — hence the need for approved contractors.

Wethertex OT25 Timber Protection

Though not a wall coating, many approved contractors install it for:

- Soffits

- Fascias

- Outbuildings

- Timber cladding

Its long-term UV stability and flexibility make it preferable to standard wood paint.

5. How a Property Is Assessed for Wethertex Coatings

Approved contractors conduct a thorough seven-step diagnostic survey before recommending a system.

1. Full Exterior Visual Inspection

Identifies:

- Cracks

- Bblown render

- Algae growth

- Previous paint issues

- Structural irregularities

2. Moisture Readings

Using digital moisture meters ensures the substrate is within safe limits. High moisture indicates:

- Trapped water

- Rising damp

- Defective render

Coatings should never be applied over damp walls.

3. Crack Mapping

Hairline cracks require flexible systems. Structural cracks require deeper repair.

An untrained installer may hide the problem instead of fixing it.

4. Render Type Identification

Whether the render is:

- Sand & cement

- Monocouche

- Pebble-dash

- Lime render

- Painted substrate

… determines the correct Wethertex system.

5. Hollow Render Testing

Approved contractors tap-test render to detect:

- Delaminated sections

- Void areas

- Areas requiring removal

6. Colour Fade & Surface History Analysis

This identifies:

- UV damage

- Previous coatings

- Potential adhesion problems

7. Guttering & Downpipe Check

Issues like leaking gutters can undermine even a perfect coating.

This diagnostic survey ensures that the coating is not only applied — but applied correctly for long-term success.

6. The Installation Process Step-by-Step

1. Cleaning & Biocide Treatment

High-pressure washing removes:

- Dirt

- Algae

- Moss

- Loose coatings

Then a biocide is applied to ensure future stability.

2. Render Repairs & Substrate Stabilisation

This may include:

- Removing hollow areas

- Rendering repairs

- Crack stitching

- Mesh reinforcement

- Profile restoration

3. Masking & Protection

Professional masking protects:

- Windows

- Soffits

- Cars

- Driveways

- Plants and landscaped areas

Spray systems require precise protection.

4. Primer Application

Primers must match the substrate:

- AX1 for chalky surfaces

- SL1 for stabilisation

- CP1 for deeper penetration

Wrong primer = failed coating.

5. Spray Application of Coating

This requires:

- Correct viscosity

- Calibrated pressure

- Correct nozzle size

- Controlled movement

- Build-up technique

The coating is applied in layers to achieve the required dry film thickness.

6. Final Quality Check & Customer Walkthrough

Approved contractors perform:

- Thickness checks

- Adhesion checks

- Visual inspection

- Final clean-up

Then they walk the customer through the result before issuing the guarantee. Here's our own exterior wall coatings process.

7. How Wethertex Contractors Are Vetted & Trained

Image Source: Wethertex.co.uk

To become approved, contractors must pass:

1. Technical Product Training

Learning:

- Chemistry behind the products

- Correct surfaces for each system

- Performance behaviours

- Drying and curing cycles

2. Practical On-Site Training

This includes:

- Mastering spray machines

- Achieving correct film thickness

- Handling specialist primers

- Applying texture finish coats

3. Knowledge Testing

Installers must demonstrate:

- System design understanding

- Moisture behaviour knowledge

- Substrate diagnosis skill

4. Quality Audits

Wethertex routinely checks installer work to ensure:

- Consistent results

- Product integrity

- Compliance with standards

This ensures that homeowners always get a certified professional.

8. Common Problems Caused by Non-Approved Installers

Homeowners often experience failures within just 12–36 months when using non-approved installers.

Common issues include:

1. Cracking

Due to incorrect:

- System choice

- Film thickness

- Primer selection

2. Peeling or Flaking

This happens when:

- Substrate wasn’t stabilised

- Chalky surfaces weren’t primed

- Coating was applied too thin

3. Trapped Moisture

Leads to:

- Damp patches

- Bubbling

- Delamination

4. Colour Variation

Caused by uneven spray pattern or incorrect mixing.

5. Voids & Hollow Areas

If blown render isn’t repaired, the coating will fail.

6. Warranty Invalid

Non-approved application = no manufacturer support.

These problems cost homeowners thousands to fix, making approved contractors the smarter choice from the beginning.

9. How to Check Whether a Contractor Is Wethertex Approved

Homeowners should always verify approval using these steps:

1. Ask for Their Wethertex Accreditation Certificate

Approved installers receive a physical and digital certificate.

2. Check Their Website

Approved contractors usually display:

- Wethertex logo

- Approved contractor badge

- Product training information

3. Request Proof of Training

Installers can show training records.

4. Contact Wethertex Directly

Wethertex can confirm approval:

- By phone

- By email

- Via their head office

https://www.wethertex.co.uk/find-a-contractor/

If a contractor hesitates or makes excuses — they are not approved.

Why Wethertex MP44 & Other Products Perform Best When Installed Professionally

Wethertex MP44 and related systems are engineered coatings, not general masonry paints.

They require:

- Controlled spray technique

- Specific film thickness

- Correct primers

- Substrate moisture testing

- Consistent application

- Incorrect application may cause:

- Solvent entrapment

- Micro-cracking

- Adhesion failure

Approved contractors ensure optimum performance and guarantee validity.

Conclusion

Choosing a Wethertex Approved Contractor protects your home, guarantees performance, and ensures long-term value. Wethertex coatings are premium-grade protective systems — and their success depends on correct installation. With approved applicators like Pinnacle Wall Coatings, homeowners benefit from:

- Guaranteed product performance

- Correct preparation and installation

- Long-term durability

- Peace of mind

- A high-quality finish

- Full manufacturer-backed warranties

If you're considering exterior wall coatings, it pays to do it right the first time.

Get a Wethertex-approved no obligation quote today...

We have teams located across the whole of England & Wales with two main offices - GET A FREE, 'no obligation' quote.

We GUARANTEE to beat ANY genuine like for like quote!!!

London Office: Daws House, 33-35 Daws Lane, London, NW7 4SD

South West Office: The Apex, Derriford Business Park, Brest Road, Plymouth, PL6 5FL